lire la suite

lire la suite

Chez Inpackt, nous sommes fiers d'être reconnus comme des leaders mondiaux dans le domaine de l'emballage.

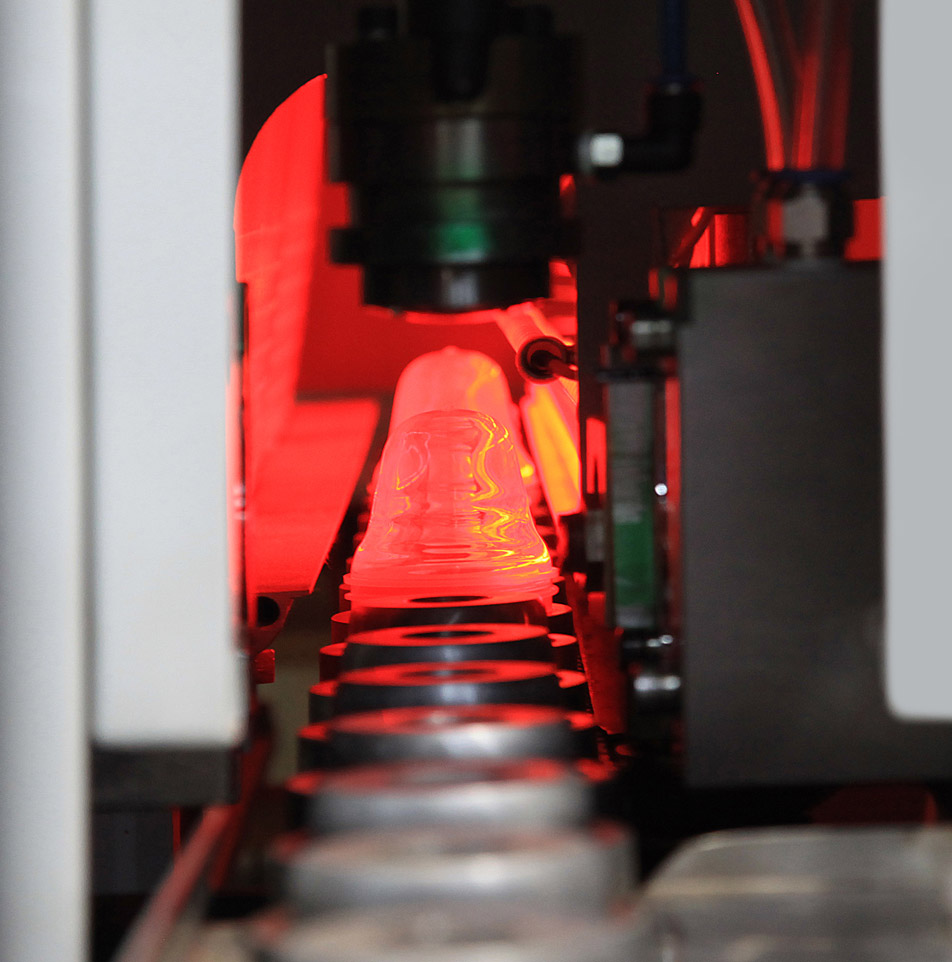

Nous nous spécialisons dans la fabrication de préformes PET et RPET de haute qualité. Nos produits sont conçus pour répondre aux exigences strictes de performance et de durabilité, tout en respectant les normes environnementales.

Savoir plus

Savoir plus

Chez Inpack, nous nous engageons à fournir des solutions d'emballage de la plus haute qualité grâce à notre expertise technologique avancée.

Faites-nous confiance pour être votre partenaire de choix en solutions d'emballage.

Plus d'information

Plus d'information

Chez Inpackt, nous nous engageons à offrir des solutions innovantes pour l'industrie de l'embouteillage en PET, tout en soutenant la croissance et le succès de nos clients.

Depuis 2004, INPACKT se positionne comme un acteur clé en Tunisie dans la production de préformes et de bouchons en plastique PET de haute qualité. Grâce à un parc de machines de dernière génération, nous assurons une production rapide, efficace et conforme aux délais les plus stricts. Notre service de contrôle qualité, soutenu par des analyses en laboratoire, garantit une qualité irréprochable, de la matière première au produit fini. En constante innovation, nous adaptons notre gamme de préformes PET pour répondre aux exigences croissantes des embouteilleurs en Tunisie. Cette approche nous permet de satisfaire les besoins du marché local tout en respectant les normes internationales. INPACKT continue d’évoluer pour offrir des solutions de packaging durables, alliant performance et respect de l’environnement, contribuant ainsi à l’essor de l’industrie des boissons en Tunisie et au-delà.

Inpackt Tunisie est à la pointe de la fabrication de préformes et bouchons en plastique PET, offrant des solutions de haute qualité pour diverses industries. Grâce à des installations ultramodernes et une expertise éprouvée, nous produisons des préformes et bouchons robustes et durables, répondant aux standards internationaux les plus stricts. Nos processus incluent le moulage par injection de précision, utilisant des matières premières sélectionnées pour garantir des performances optimales. Engagés pour l’innovation continue et la durabilité, nous développons des produits sur mesure pour les secteurs de l’alimentation, de la pharmacie, de la cosmétique et de la chimie. Inpackt s’efforce de répondre aux besoins du marché local et international, en fournissant des emballages fiables, respectueux de l’environnement, qui renforcent la compétitivité de nos partenaires industriels.

Nos bouteilles en PET pour eau garantissent pureté, fraîcheur, et résistance. Légères et entièrement recyclables, elles sont disponibles en plusieurs formats pour répondre à tous les besoins des consommateurs.

Nos bouteilles pour huile, robustes et ergonomiques, assurent une manipulation facile et un versement précis. Conçues pour protéger contre la lumière et l’oxydation, elles préservent la qualité et la fraîcheur des huiles.

INPACKT offre des bouteilles spécialement conçues pour les boissons gazeuses. Résistantes à la pression interne, elles garantissent une conservation optimale du goût et de la gazéification, assurant qualité et durabilité.

INPACKT propose une gamme variée de bouchons en plastique PET, adaptés à tous types de bouteilles. Conçus pour une fermeture sécurisée et hermétique, nos bouchons garantissent la conservation optimale des contenus. Disponibles en divers formats et designs.

Nos bouteilles pour détergents, durables et résistantes aux produits chimiques, sont conçues pour une utilisation pratique et sécurisée. Équipées de bouchons hermétiques, elles préviennent les fuites et garantissent une manipulation sûre.

Chez Inpackt Tunisie, nos valeurs fondamentales guident chaque aspect de notre activité. Nous nous engageons à offrir une qualité supérieure et à stimuler l’innovation dans la production de produits en plastique robustes et fiables. Notre engagement envers la durabilité se manifeste à travers l’utilisation de matériaux recyclables et de pratiques éco-responsables. La satisfaction client est au cœur de notre mission, avec des solutions personnalisées adaptées à chaque secteur industriel. Nous fournissons un service exceptionnel pour répondre aux besoins spécifiques de nos clients, garantissant ainsi des résultats optimaux et un impact positif sur l’environnement.

Grammages proposés : 20g, 50g, 100g, 200g, 500g,

Types de colle : Colle blanche, Colle transparente, Colle forte, Colle à prise rapide, Colle spéciale pour matériaux spécifiques (bois, métal, plastique, etc.)

INPACKT est en activité depuis 2004, fournissant des produits de haute qualité aux embouteilleurs en Tunisie et dans les pays africains.

INPACKT dispose d’un service de contrôle qualité qui analyse les matières premières et les produits finis dans notre laboratoire. Cela garantit que chaque produit respecte nos normes élevées de qualité.

Oui, INPACKT est capable de s’adapter aux besoins spécifiques de ses clients en proposant des solutions personnalisées en termes de préformes et bouchons en plastique.

Vous pouvez obtenir un devis en nous contactant directement via notre site web ou en envoyant un e-mail à notre service commercial. Nous serons ravis de vous fournir un devis détaillé selon vos besoins.

Les délais de livraison varient en fonction de la commande, mais grâce à notre parc de machines moderne, nous sommes en mesure d’assurer des délais optimaux pour la satisfaction de nos clients.

Oui, INPACKT offre un service après-vente pour garantir la satisfaction continue de nos clients. Nous sommes disponibles pour toute assistance ou question après l’achat.

Vous pouvez nous contacter via notre formulaire de contact sur le site web, par e-mail ou par téléphone. Nos coordonnées complètes sont disponibles sur notre page de contact.

Nous travaillons avec INPACKT depuis plusieurs années, et nous sommes toujours impressionnés par la qualité de leurs préformes PET et bouchons en plastique. Leur parc de machines de dernière génération assure une production rapide et fiable. Leur service de contrôle garantit que chaque lot respecte nos exigences élevées en matière de qualité. Nous recommandons vivement INPACKT pour leurs produits de haute qualité.

INPACKT est notre fournisseur de confiance pour les préformes PET depuis 2004. Leur engagement envers la qualité et l'innovation est évident dans chaque produit qu'ils livrent. Grâce à leur laboratoire de contrôle, nous avons toujours l'assurance que les matières premières et les produits finis répondent à nos standards. Leur gamme évolutive répond parfaitement à nos besoins croissants.

Nous avons choisi INPACKT pour leur capacité à fournir des préformes et bouchons en plastique de haute qualité dans des délais optimaux. Leur parc de machines modernes et leur service de contrôle rigoureux nous donnent une grande tranquillité d'esprit. INPACKT a su évoluer avec le marché pour répondre à nos besoins, que ce soit en Tunisie ou sur le marché africain.

Travailler avec INPACKT a été une excellente expérience pour notre entreprise. Leur production de préformes PET et de bouchons en plastique est non seulement de qualité supérieure, mais également rapide grâce à leur équipement de pointe. Le service de contrôle d'INPACKT assure que chaque produit est conforme à nos spécifications, ce qui est crucial pour notre production.

INPACKT s'engage fermement dans une démarche éco-responsable. Nous utilisons des matériaux recyclables et des processus de production respectueux de l'environnement.

Nos produits sont conçus pour offrir un gerbage optimal. Cela garantit une stabilité maximale lors du stockage et du transport, permettant ainsi de réduire les risques de dommages et d'optimiser l'espace.

INPACKT est fier de ses nombreuses certifications qui attestent de la qualité et de la conformité de nos produits. Ces certifications garantissent à nos clients des produits répondant aux normes internationales les plus strictes.

Nos solutions de packaging sont réputées pour leur robustesse. Conçus pour résister aux conditions les plus exigeantes, nos emballages protègent vos produits de manière optimale, assurant une livraison en parfait état.

Chez INPACKT, nos valeurs fondamentales sont l'intégrité, l'innovation et l'excellence. Nous croyons en une collaboration transparente et éthique avec nos clients, partenaires et employés.

Nous nous engageons à fournir des produits de la plus haute qualité, à respecter l'environnement et à maintenir une amélioration continue de nos processus. Notre engagement envers nos clients est de toujours dépasser leurs attentes.

Forts de nombreuses années d'expérience, nous disposons d'une expertise approfondie dans la fabrication de préformes PET et de bouchons en plastique. Notre savoir-faire technique et notre innovation constante nous permettent de proposer des solutions adaptées aux besoins de nos clients.

La mission d'INPACKT est de devenir le leader incontournable dans la production de préformes PET et de bouchons en plastique, tout en mettant l'accent sur la durabilité, la qualité et la satisfaction client.